In last week’s post, we talked about AquaLazing. AquaLazing, also known by names such as Hydrolazing and Hydromilling, is an advanced high-pressure water jetting process. With AquaLazing, timing and training is everything.

When done right, AquaLazing can effectively clean piping systems of mill-scale, construction debris, and process deposits. In addition to piping systems, AquaLazing can be used to clean other critical plant components which can become contaminated with water or process deposits.

Proper or optimal results require proper training and expertise, Without these, the results can be ineffective—particularly in pre-commissioning cleaning situations.

Ineffective pipe cleaning is typically the result of poor training. You must be able to calculate proper speed based on the internal diameter to eliminate the spiraling effect that left this mill scale and debris behind. All of these factors require an experienced decision-maker calling the shots.

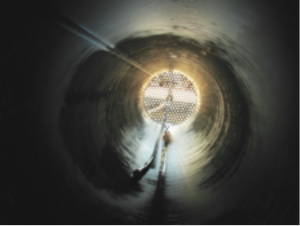

When properly aqualazed, piping looks like this: all construction debris and mill scale removed.

AquaLazing can be used as a primary method for cleaning or in conjunction with other pre-commissioning cleaning services such as Steam Blowing and Air Blowing to help reduce overall cleaning times and associated costs.

In many cases, AquaLazing can also be applied to piping systems typically requiring Chemical Cleaning to achieve the same cleanliness level, at reduced costs and zero environmental impact. Drying of cleaned systems followed by the application of a corrosion inhibitor can be accomplished to facilitate cleaning systems ahead of schedule and ensure ready for start-up.

Not all Aqualazing, Hydrolazing, and Hydromilling service providers are the same. Smart choices will require more than a response to an RFP. B&W can provide photos, videos, references. Ask us for a demonstration. Informed choices will be the key to your projects success.