Efficient plant start-ups hinge on clean piping systems. Mill scale, weld slag and construction debris often get left behind after construction is complete. If these contaminants aren’t properly removed before startup, they can travel downstream and wreak havoc on your plant equipment during operation.

For steam systems, an effective steam blowing program will eliminate these problems. The industry standard for steam blowing is to create dynamic pressure throughout the piping system that is at least 20% higher than would be experienced in normal operating conditions (CFR ≥ 1.2). This ensures that any loose or adhered contaminants will be blown out of the piping system before plant operation.

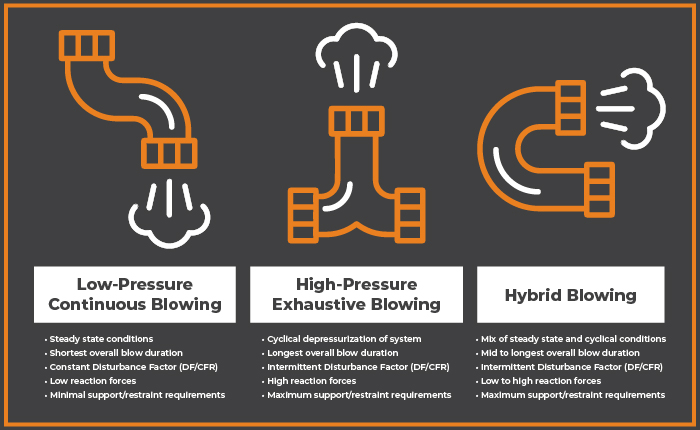

There are several different types of steam blow methods available which are implemented based on each specific project’s needs. These include:

The most common steam blow method today, continuous low-pressure blowing has the shortest overall blow duration, and a constant disturbance factor with continuous high velocities throughout the system. It has low reaction forces and minimal support/restraint requirements.

This has the longest overall blow duration and features a cyclical depressurization of the system with an intermittent disturbance factor. It includes high reaction forces and maximum support/restraint requirements.

In certain situations, a mix of steady-state and cyclical conditions works best. This hybrid blowing features mid-level to the longest overall blow duration and an intermittent disturbance factor. Reaction forces range from low to high with maximum support/restraint requirements.

Finding the right steam blowing partner is crucial to plant start-up success. It can ensure safety on your project and save you money and schedule.

One thing that sets B&W Energy Services apart is our large inventory of specialized steam blow equipment, strategically located to accommodate rapid mobilization to major energy projects worldwide. This includes pre-fabricated temporary vent piping system built to ASME B31.3 code, steam silencers (wet and dry type), pneumatic target inserters, and other specialized equipment. B&W maintains the largest inventory of Dry Silencers in the industry, enabling us to drastically reduce project costs and environmental impact by reducing project water consumption during steam blowing, while still meeting the most stringent project noise requirements.

When planning for a new steam blow program, there are many factors to consider to ensure a successful execution. Several key factors include:

● Permanent system construction turnover schedules must be aligned with planned steam blow execution dates

● Sufficient steam generation capacity and utilities should be available to support required steam flow rates

● Pre-cleaning of steam systems will be evaluated, such as Aqualazing, which will drastically reduce steam blow durations for critical lines

● Sensitive system components must be removed and spooled; temporary spools may be utilized from construction hydrotest materials

● A sufficient quantity of temporary steam blow vent piping system and equipment must be mobilized and coordinated to minimize gaps between steam blow iterations

● Adequate site mechanical resources must be allocated to keep up with installation of equipment and system preparations

During the planning stage, B&W’s engineering team will help your project navigate and plan for these events. A detailed engineering package will be developed to include all procedures, drawings and checklists to ensure smooth program execution. The steam systems will be modeled and analyzed by an experienced B&W Project Engineer for proper cleaning velocities and disturbance factors. Accurate modeling will lead to verifiable results and compliance with all client and OEM specifications.

All of this detailed planning will be compiled into a comprehensive steam blow execution package, which will be used by our team of Project Managers to ensure the program is executed safely and effectively in the field.

Our Record Speaks for Itself

Complex projects require a special contractor with proven experience and expertise to help clients achieve success. Over the past 20 years, B&W has successfully engineered and executed more than 170 steam blow projects in 22 countries, with over 4000 unique steam blows performed. The knowledge our team has gained over the years makes B&W uniquely qualified to tackle any steam blow project, large or small.

If you’re looking for a partner to meet your steam blow needs, consider working with the company with better people, better equipment and better engineering. It’s not just our tagline – it’s who we are.