If your company is one that contributes to the production of ethylene, you know that the process is the third highest production operation of the petrochemical industry. More than 120 million tons of ethylene are produced a year, with a steady growth of four to five percent annually. The prevalence of the production of these chemicals means it’s vital to secure the maximum performance level of your equipment, including your uniquely designed ethylene furnaces. That’s where B&W comes in.

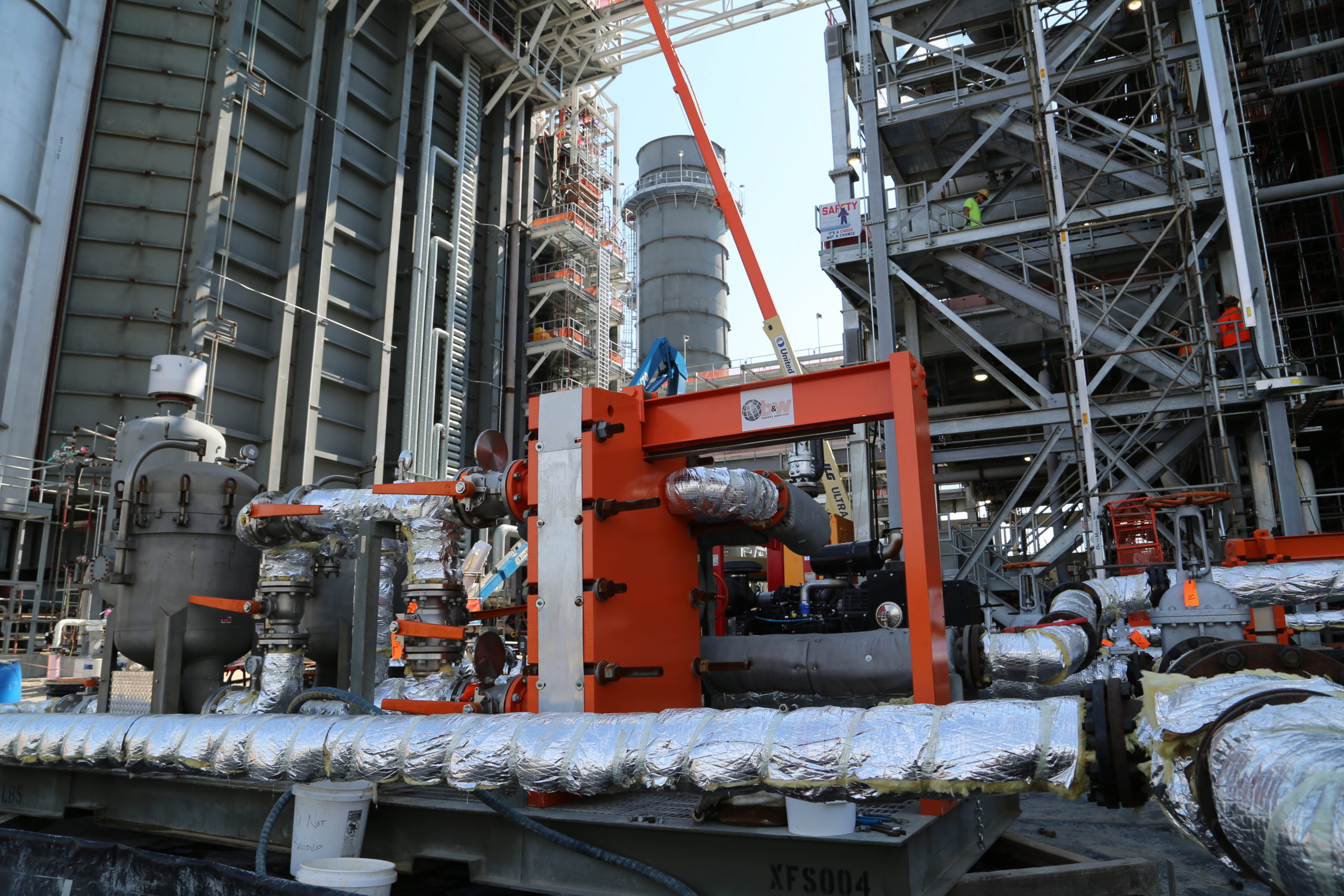

B&W understands that there are many components to an ethylene furnace. These intricate, multi-stage systems require detail-oriented planning for the successful execution of pre-commissioning cleaning. Internal temporary manifolds may need to be designed to allow for flow redirection to other paths of the system or to ensure proper velocities and coverage. This action might be required when there are no suitable flow paths within the design of the furnace itself and where flow may need to be rerouted to allow for an inclusive cleaning flow path scenario for other parts of the system. This creates a single cleaning matrix by providing flow to those components. B&W might also suggest temporary manway covers that seal the furnace drum and provide an inlet for new flow direction, ensuring correct flow and coverage. A complete understanding of the distinctive design of each furnace is necessary when performing cleanings, as well as total knowledge of each one’s flow characteristics and the corresponding metallurgy.

B&W is poised to provide your organization with the pre-commissioning assistance for your ethylene furnace designed to set you up for success. We harness decades of experience and have the top experts in the industry, who’ve completed the cleaning of furnaces across the world.

With time and attention to the cleaning processes, B&W will help your projects run smoothly so you can hit your goals and objectives without delays. If you’re looking for better people, better equipment and better engineering, B&W is the partner for you. Give us a call today to learn more about our pre-commissioning and commissioning services. You can learn more about B&W’s hands-on experience cleaning ethylene furnaces by checking out our “All Systems Go – Ethylene Furnace Technologies” whitepaper.