Steve Jobs once said, “Innovation distinguishes between a leader and a follower.”

At B&W, we understand that in order to lead an industry, you must research, develop and seek new processes that save time and cut costs for everyone. This process requires continued innovation — the kind of innovation that B&W Energy Services has developed, and continues to seek, so that we may continue to deliver real impact for our customers.

B&W Energy Services has brought a series of innovations to the pre-commissioning cleaning industry that have been widely recognized for their project savings around the world.

Piping Systems Chemical Cleaning Alternative

In the past, long piping systems required chemical cleaning processes per the specifications posed due to their operational applications. This often translated into many set-ups and relocations. It required the handling and storage of chemical waste throughout the project. What if you could eliminate some of these costs? Now we can.

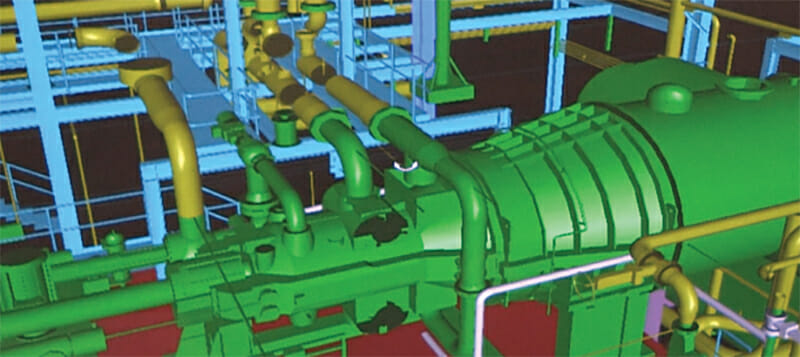

Since B&W Energy Services has introduced our AquaLazing high-pressure, internal pipe cleaning services, many new applications for this service have evolved. Take for example, large bore compressor suction piping. This piping typically required some kind of chemical cleaning which involved extensive set-up with poor circulation capabilities, plus it involved waste handling, storage and disposal. AquaLazing all but eliminated these potential issues and provided major schedule reduction and substantial cost savings.

Power Plant Cleaning Alternative

Often, OEM specifications for new power plants require a full chemical cleaning of the boiler and steam piping. This cleaning process involves a massive chemical cleaning set-up making it necessary to pass through the superheated sections to incorporate the steam piping. This invariably leads to hazardous chemical waste issues due to the exotic metals used in superheat piping systems.

B&W Energy Services started thinking outside the box — we use our high-pressure AquaLazing internal pipe cleaning services to clean the steam piping prior to performing steam blows. This process reduces the scope for the chemical cleaning and eliminates the need to handle potentially hazardous chemical waste altogether.

Taking this time-tested technology one step further, B&W employs AquaLazing to clean air cooled condensers (ACC), allowing the water quality to come up to specifications much quicker during start-up. This reduces time to start-up at a lower cost than typical closed loop steam cleaning of the ACC during commissioning. Customers have welcomed these substantial project cost savings due to B&W’s innovative AquaLazing solution.

Steam Blow Noise Reduction

Many projects experience steam blow challenges due to location and the real estate needed to perform the service. Typical steam blow setups require a certain length of temporary piping to allow for quenching or cooling the steam in addition to the deceleration process to help with acceptable noise reduction at the exhaust point. Some projects just don’t have enough room to accommodate this set-up. B&W identified a need for innovation, and developed the largest fleet of dry silencers in various sizes and configurations, which allows for greater flexibility to meet the unique requirements of end projects.

As B&W Energy Services continues to grow, we have made a commitment to never stop innovating — passing along the benefits of those innovations to you, our valued clients.