There’s one crucial step that stands in the way between construction and pre-commissioning: hydrostatic testing. This process has the ability to either maximize your facility’s longevity or maximize costly downtimes and repairs. Keep reading to understand how to achieve the former.

What is Hydrostatic Testing?

Hydrostatic testing is a process that aids in leak detection and is used to evaluate the strength and integrity of pressure containing equipment. It ensures the structural integrity of piping systems, vessels, boilers, HRSGs and other components within a facility. This process occurs after construction and is required before a project moves on to the pre-commissioning and commissioning stages. Hydrostatic testing may also be performed to determine whether a component was repaired or rebuilt properly.

What’s the Difference Between a Hydrotest and a Hydrostatic Test?

Similarly to AquaLazing and hydrolazing, hydrotesting and hydrostatic testing are synonyms for the same procedure. Hydrostatic testing, or hydrotesting for short, derives its name from the Greek “hudro,” meaning “water,” and “statikos,” meaning “causing to stand.”

How Does Hydrostatic Testing Work?

Step 1: The B&W Energy Services team temporarily isolates the selected piping system section or vessel by closing valves or installing temporary isolation blinds.

Step 2: The team excavates the selected section of piping to expose the ends of the piping system. One end of the pipeline segment is removed and capped with a test head cap to ensure an airtight seal. The test head cap also contains a foam plug, similar to a pig.

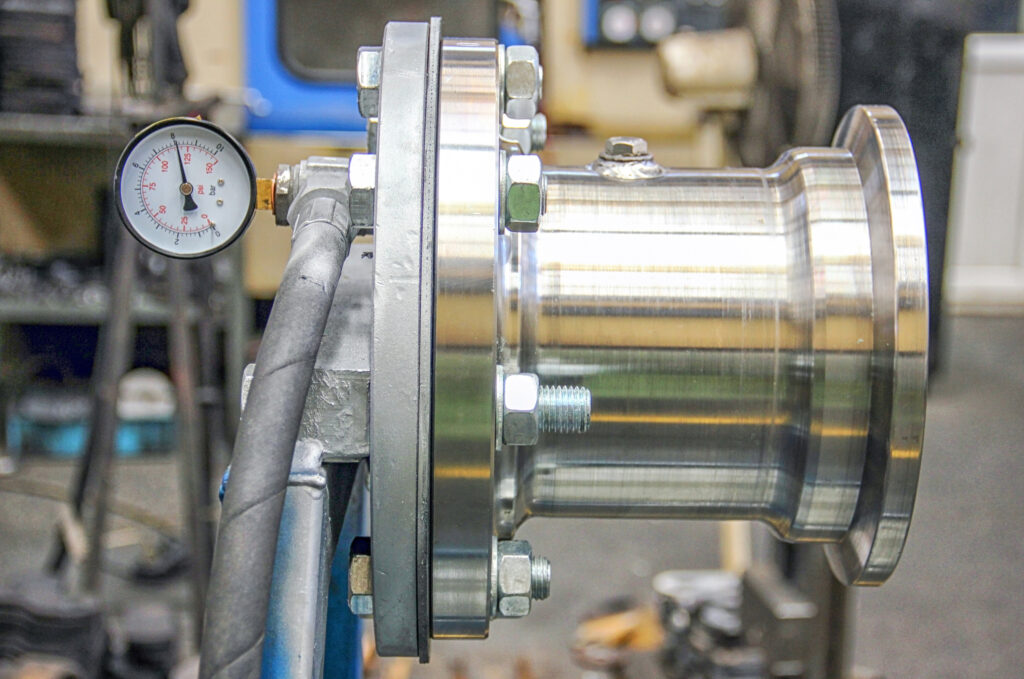

Step 3: Using a high-pressure pump, water is pumped through the piping system or vessel via a testing manifold in a controlled sequence that forces the remaining air out of the system as it’s replaced with water. For certain vessel applications, the water is heated to above ambient temperature as required by applicable codes.

Step 4: The team gradually increases the water pressure to a point higher than the average operating pressure to test the piping system’s structural integrity. This is commonly 1.5 times the system’s design pressure for ASME B31.1 and B31.3 piping codes.

Step 5: After maintaining said pressure for at least eight hours, or as required by the hydro test procedure, the hydro test (or hydrostatic test) is complete!

Following a successful hydrotest, the system is drained completely and either put back into service or prepared for pre-commissioning.

If the team detects any signs of damage during the hydrostatic test, including leaks or cracks, the damaged sections will be repaired or completely replaced, depending on the results of the test.

How Often Should I Perform Hydrostatic Testing On My Piping Systems?

Some in the industry say to schedule hydrostatic testing once every year. At B&W Energy Services, our goal is to save you time and money by ensuring that hydrotesting services are of the highest quality the first time.

We perform hydro testing and pre-commissioning cleaning services together to minimize costly downtimes for your facility. Why disassemble your control valves and other system components several times when you can get everything done in one go? With advanced engineering and top-tier employees and equipment, we’re dedicated to serving you. How can B&W help you through our hydrotesting services?