B&W Gets the Job Done Right the First Time

Do you know the best way to prepare your project for success when cleaning air-cooled condensers (ACC)? The right service provider will. For ACC systems, utilizing the latest cleaning processes in the industry will not only help improve schedule predictability for your project but will also significantly reduce resources during plant commissioning. That’s where B&W Energy Services comes in with AquaLazing.

AquaLazing

B&W’s AquaLazing service is a state-of-the-art cleaning method that is both efficient and environmentally conscious. The method uses an advanced, high-pressure water-jetting process, which can effectively clean ACC of scale, construction debris and other contaminants. No chemicals are used during the cleaning process, and the water used for jetting can be contained and recirculated to minimize consumption and waste. Alternatively, at sites where water consumption is not a concern, it can be filtered and safely routed to an approved discharge location.

B&W’s engineering team will evaluate your ACC system and design a plan for the most effective cleaning. This includes addressing cleaning the main areas of an ACC: streets, collection headers and turbine exhaust duct(s). All system preparation, cleaning and reinstatement steps will be clearly identified. When cleaning of ACC systems is combined with AquaLazing of other plant systems like condensate, feed water and steam piping, you can be assured that steam blows will be performed in the shortest duration possible during commissioning.

B&W uses the most advanced, high-pressure pumping equipment available in the industry, and cleaning nozzle designs have been refined based on decades of experience. B&W prioritizes safety every step of the way with proper equipment safeguards, expertly engineered cleaning packages and extensive personnel training.

The AquaLazing Difference

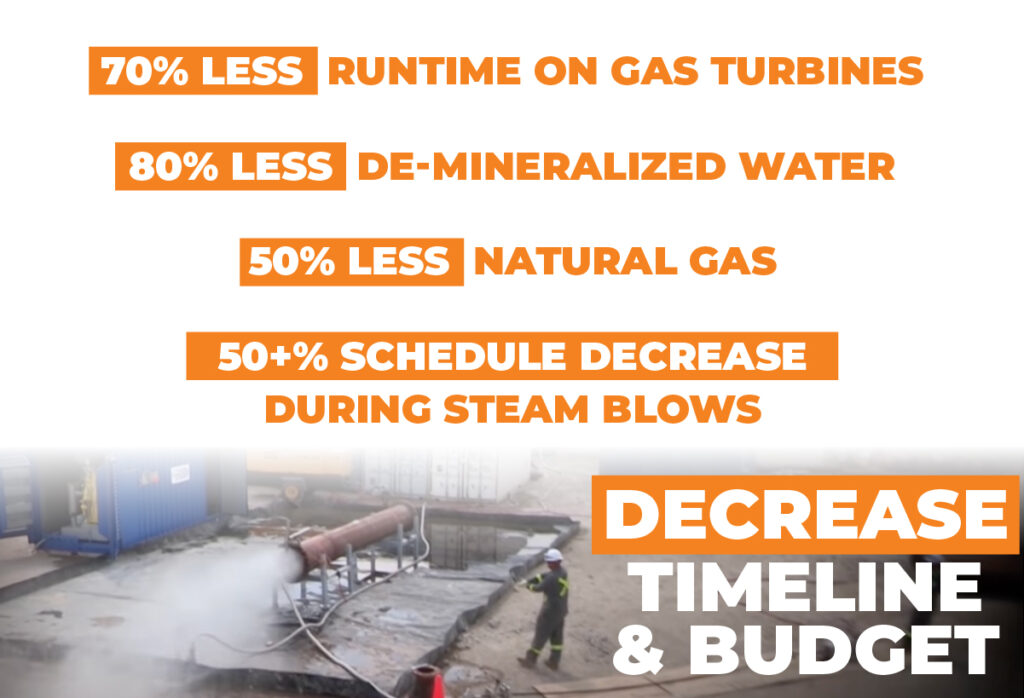

When it comes to steam blows and commissioning, the contrast between a project with and without AquaLazing is stark. A traditional project without AquaLazing can take, on average, an estimated 300 to 400 hours of runtime per gas turbine to complete steam blows. These systems can also use up to 30 million gallons of demineralized water and huge volumes of natural gas to run turbines for the duration of steam blowing.

Not with AquaLazing. If you’ve planned ahead and implemented this service with the support of B&W, you’ll likely cut all these numbers by half or more. With AquaLazing performed prior to steam blows, you could achieve the following:

If the time is approaching for you to plan your project’s cleaning program, ensure efficiency and success when cleaning your ACC by partnering with the experts. We’re prepared to provide your plant with the pre-commissioning services you need to achieve your goals. Give us a call today to learn more about how we can maximize your project savings.