B&W strives for safety on all fronts. Previously, we explained the importance of ensuring our people were the safest employees possible for a job. Having great workers only goes so far unless you ensure their success by providing excellent equipment to work with. This is why B&W has taken special care to supply every job site with top-notch tools and equipment. How do you do that you ask? Let us explain…

Equipment is only as good as its upkeep. Many energy service companies may have good equipment, but do not tend to the pieces as frequently as necessary. It would be like owning a car that’s long overdue for an oil change – the result would be a pretty ragged car, and the same is true with equipment. Without rigorous quality management qualifications for equipment, like B&W’s, the standard of work can slowly slip because machinery is not operating properly, or safely. For obvious reasons this becomes a concern. We’re dedicated to keeping up with our equipment because we do not want to put the people working a project, the company we are doing a project for, or the project itself at risk.

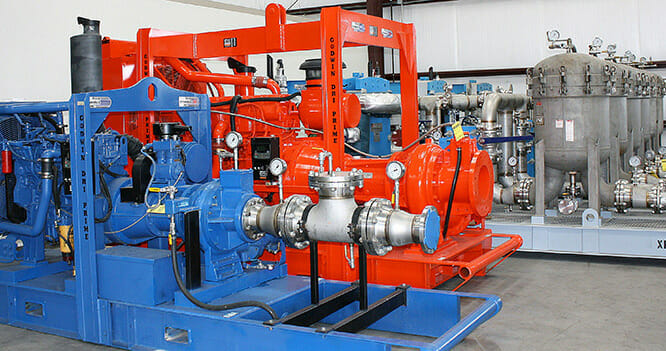

Quality management is only one aspect of ensuring safety when discussing equipment. One of the easiest ways to make certain equipment is safe to use, and one of the most overlooked ways, is to use the best materials and methods possible when making the equipment. High-quality materials may, at times, have more upfront costs—a reason this option is unattractive to some companies. In the long run, this cost pays for itself by not only producing high quality performance, but also establishing a standard of safety. B&W puts these principles in practice by only using proven, high-grade materials in our work and building equipment that is foolproof. For example, B&W uses American-made materials, which pass the highest standards, rather than sourcing materials from outside the United States. Our materials have demonstrated better results and are also made to last.

When it comes to equipment, we know how important it is for a piece to be on site as quickly as possible. The B&W founders also took this into account, and created equipment that easily fits in a shipping container and can arrive anywhere across the world efficiently. It’s packed and assembled in a way that protects the piece from being damaged during shipping and the Technical Advisor on site can easily put it straight to use. Our approach to equipment ensures each piece arrives safely at the job site, ready to go.

The equipment used on a job site directly affects the success and safety of a project. At B&W, we have used first hand experience and knowledge to create the most efficient and safest equipment possible. It’s our responsibility to make sure every effort is taken to achieve the highest level of safety and success—making B&W the best people, and equipment, for your job.