Oil Flushing

Professionally Engineered Oil Flushing Services

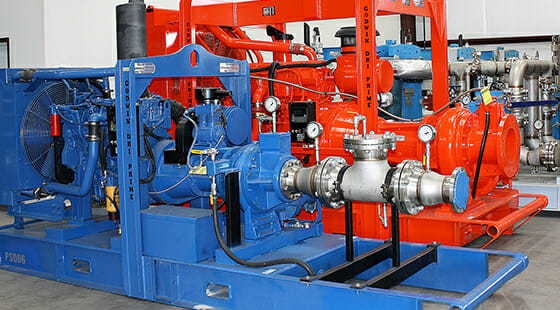

Reduce the time it takes to perform oil flushing services from months to weeks or even days. Thanks to years of experience executing oil flushing services, B&W Energy Services is able to shorten traditional oil flushing timelines. Our high-velocity flushing skids are designed by our in-house engineering team and include integrated pumping, filtration and heating components for minimum footprint during setup. This gives our team rapid mobilization capabilities and reduces rig-up time once on site. We can achieve a wide range of flow rates to ensure that system cleanliness is completed in significantly less time than onboard equipment, and all our temporary hoses, fittings and equipment arrive pre-cleaned to eliminate the risk of further contaminating a lube oil system once mobilized.

B&W Energy Services has experience flushing critical rotating equipment for manufacturers including:

- Altsom

- Toshiba

- Mitsubishi

- Siemens

- Dresser-Rand

- Caterpillar

- General Electric

- Elliott

Start Flushing Today

B&W Energy has designed specialized equipment necessary to perform high-velocity turbulent lube oil flushing and filtration of lube oil and control oil systems, commonly found on critical rotating equipment. Effectively cleaning these systems is imperative as the lubricated components have extremely tight tolerances regarding the cleanliness condition of the lubricating medium.

B&W evaluates the entire system to be flushed clean by utilizing all design inputs such as process and instrumentation diagrams, erection isometrics, vendor drawings and data sheets, metallurgy and target contamination. All client, owner and vendor specifications and guidelines are reviewed and incorporated into the engineered procedure. Incompressible fluid modeling is then performed to ensure design flow rates and velocities will be achieved during the fluid circulation, and also ensures proper temporary equipment sizing for achieving proper Reynolds numbers during flushing.