Need help determining which pigging application is suitable for your project? Learn more about the ins and outs of pigging with B&W Energy Services’ comprehensive resource collection.

What is pigging, and why is it important?

Pigging is a cleaning method that removes debris from the interiors of piping systems. It uses devices called “pigs” that travel through a pipeline to clean surfaces effectively. It’s the first step of the pre-commissioning process, as a system must be properly cleaned before pre-commissioning can begin.

Depending on the kind of piping system being pigged, pigging services may be performed semi-annually or even weekly in your facility. For example, product lines or lines containing dry gas may be pigged quarterly or semi-annually. Crude oil lines near production may be pigged weekly or bimonthly.

Pigging maintains the integrity of your piping systems by keeping them clean. The more clean your piping systems are, the longer they will last and the more time and money your facility will save.

What are the best use cases for pigging?

Pigging is generally used to:

- Maintain clean piping systems

- Gather data pertaining to pipeline integrity

- Detect leaks and other weaknesses within piping systems

- Separate, or batch, different products to prevent cross-contamination

Due to pigging’s versatility, it lends itself to a variety of purposes. At B&W, our pigging services are primarily focused on cleaning applications inside new and existing plants. However, whether you need to clean, batch or inspect your piping systems, there is a corresponding subcategory of pigging for your project out there.

Although it’s a highly effective cleaning method, pigging poses risks as well. A common pitfall of pigging is the possibility of “stuck pigs.” This refers to the cleaning device, or pig, becoming lodged within a pipeline. However, this problem may be easily solved by removing pressure and allowing a pig to its original shape.

What are the key differences between utility and inspection pigging?

Utility and inspection pigging are two of the most commonly utilized pigging categories in the industry, and they each have distinct use cases.

Utility pigging is used to maintain piping systems while inspection pigging is used to inspect piping systems. Inspection pigging is typically performed before repairs occur. Then, utility pigging comes in to thoroughly clean the piping system. At B&W, we solely offer utility pigging services.

What are the most common types of utility pigging?

Common varieties of utility pigs include:

- Batch pigs

- Sealing pigs

- Mandrel pigs

- Solid cast pigs

- Spherical pigs

- Foam pigs

- Gel pigs

- Ice pigs

Utility pigging can be used to clean, batch or seal the interior of a piping system. Different types of utility pigs correspond with different purposes. The kind of utility pig you choose depends on your intended use case and whether you’re working with small or large-bore piping.

Cleaning Pig

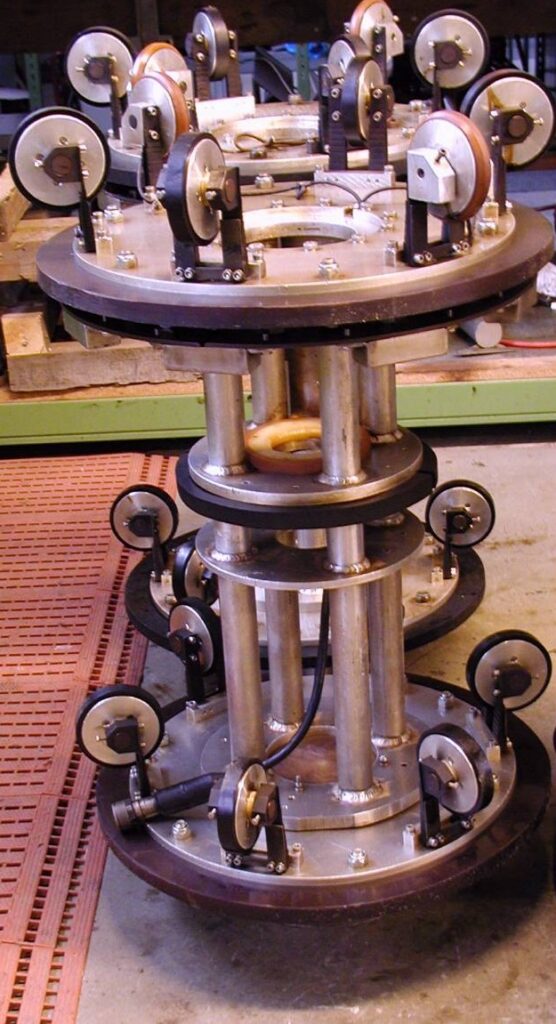

Cleaning Pig with Wire Brush

What are the most common types of inspection pigging?

Common varieties of inspection pigs include:

- Smart pigs

- Caliper pigs

- Magnetic flux leakage pigs

Inspection pigging allows engineers to inspect a pipeline. Through specialized appendages like sensors and gauge plates, inspection pigs assess the damage within a pipeline by collecting and recording incredible amounts of data.