Air Blowing

Professionally Engineered Air Blow Services

Whether you need to dewater your fuel gas system following hydrotesting or remove debris from your facility’s systems after construction, B&W’s air blowing services and proprietary equipment provide a thorough clean that strengthens the longevity of your fuel gas systems, natural gas systems, process piping, utilities and more.

For over 20 years, B&W’s team has provided air blowing services for both pre-commissioning and maintenance cleaning for folks like Chevron Phillips Chemical, Kiewit, Enterprise Products Partners L.P., Motiva Enterprises and more.

What are Industrial Air Blow Services?

Air blowing services use compressed air to efficiently clean a variety of debris from your facility’s piping systems. It’s also commonly used to dewater your facility’s systems following hydrotesting services. Find out more about the three most common kinds of air blowing here.

Air blowing may also be performed with chemical cleaning services or AquaLazing services to enhance cleanliness on your systems prior to startup activities.

Why is Air Blow Service Important?

If water, construction debris, sand, dirt and other waste remain in your facility’s piping systems after construction, these materials could lead to damage to your piping systems, equipment failure and product contamination down the line.

When your facility’s systems undergo the hydrotesting process between construction and pre-commissioning, dewatering these systems through air blowing is essential. Otherwise, your facility’s critical components can corrode, or the leftover water can freeze. Water left in a fuel gas system can have even more deadly consequences than increased maintenance and repair costs.

The B&W Industrial Air Blow Service Difference

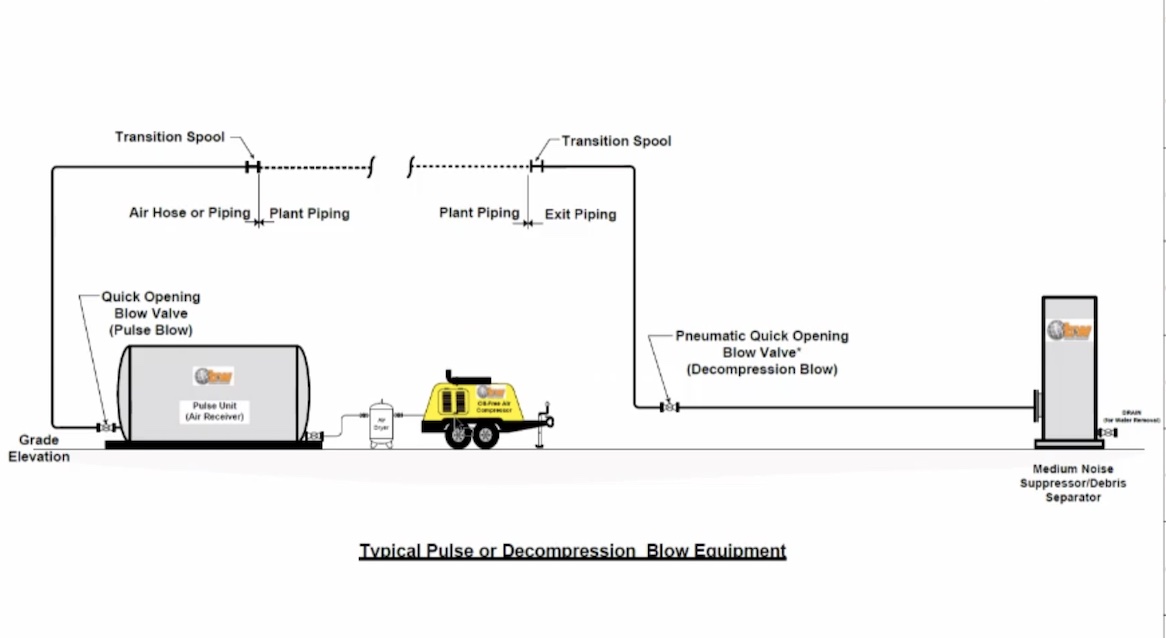

- Our proprietary, fully containerized pulse units and other specialized equipment clean your systems efficiently and effectively

- We remove even the smallest pieces of debris from your piping systems by combining the power of an air compressor with an air receiver, rather than simply pressurizing your piping and calling it cleaned

- Safety is our top priority, with:

- Zero OSHA citations and local regulatory violations in over three years

- Zero significant recordable cases in over three years

- Zero restricted work cases in over three years

- And more

How B&W Performs Air Blow Services

B&W performs air blowing services on your facility’s systems through a tried-and-true five-step process.

1. Assess

2. Model

3. Mobilize

4. Execute

5. Repeat

Curious about our proprietary air blowing equipment and how we perform air blowing services? Discover more on our blog.

Drop us a line to see how B&W’s air blow services can effectively clean your facility’s system during both pre-commissioning and MRO events.