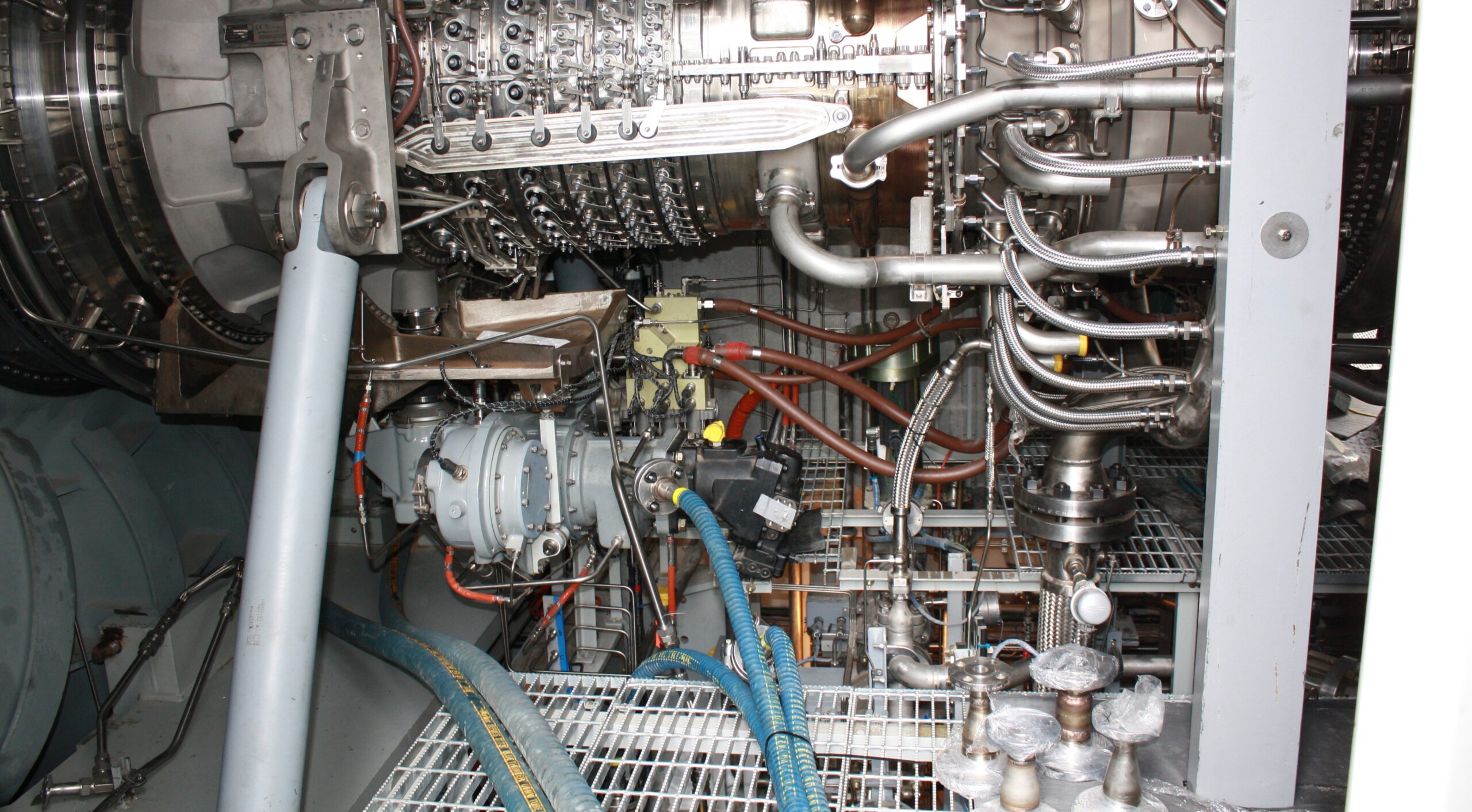

There are many different types of units that require oil flushing services prior to initial operation or startup. Air compressors, gas turbines, steam turbines and hydraulic systems—all of these have a specified OEM cleanliness procedure and standard. In the past, many machines’ cleaning phases each required a set duration, which resulted in cleaning taking more than a month or two to complete. This process was very expensive, often requiring the continuous operation of system pumps.

As the number of projects increased, a need for more providers offering industrial oil flushing services was apparent. Additionally, as units got larger, the number of bearing lines increased and oil flushing of pipes became more difficult, many oil flushing companies still used the same 1 or 2-inch hoses for their jumpers. This resulted in a highly ineffective procedure and did not reduce the duration of the flush.

With low efficiency and projects that required shorter completion schedules, a need emerged for processes that could reduce schedule and still provide the OEM level of cleanliness required to release for operation.

Engineering a Lube Oil Flush

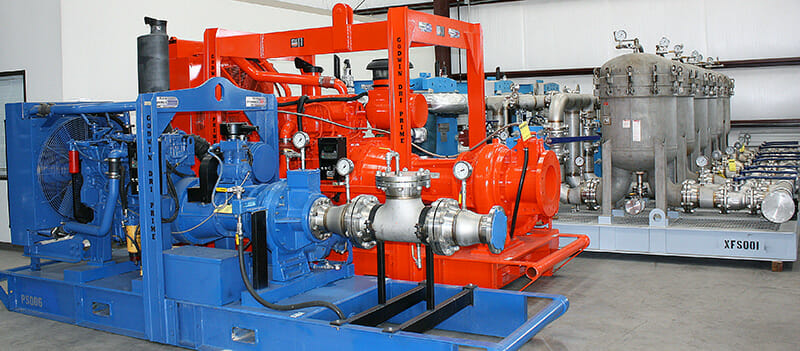

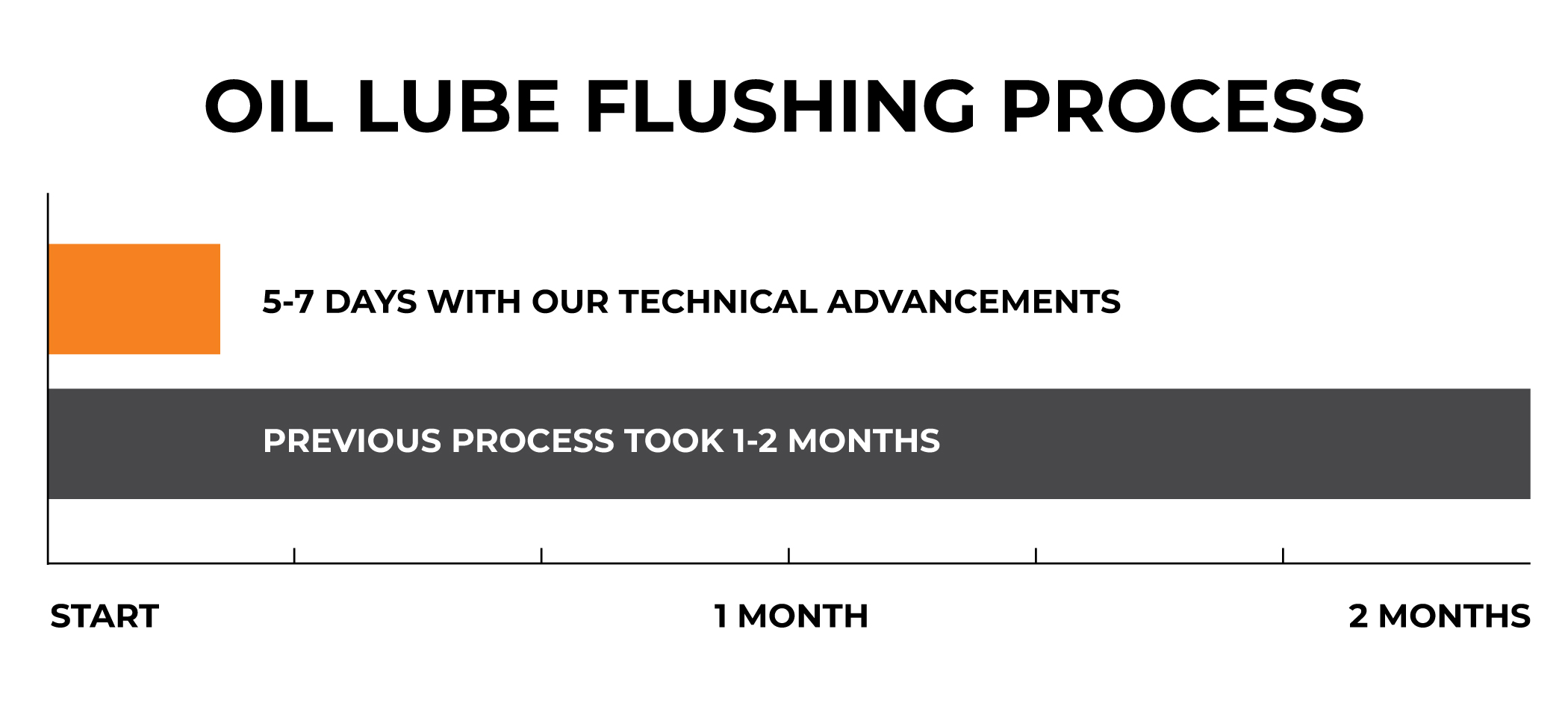

B&W Energy Services took the lead in engineering oil lube flushing services that could dramatically reduce flushing durations with superior results. By designing external pump flushing skids, we could now increase volumes and velocities. By designing high flow rate filtration systems, we could now reduce flushing durations tremendously. The high volumes and higher velocities now created the ability to heat the oil through increased friction, changing the viscosities of the oil, which helped carry debris back through the external system filtration units at an increased rate. New heat exchangers were designed for the external flushing skid in an effort to cycle the lube oil temperatures. Together, these technical advancements now produced a 5-7 day flush, versus the 1-2 month process.

Choosing The Right Provider

The advancements B&W Energy Services created for the lube oil flushing process bore valuable results. Smaller lube oil flushing providers often introduce risk to the cleaning process by not properly evaluating each system and poorly maintaining their flushing equipment. For these many reasons, B&W Energy Services’ engineered oil lube flush services became the best in the business. Let us help you with your next project and help bring your project in on time and on budget.