High-Velocity Oil Flushing

Professionally Engineered High-Velocity Oil Flushing Services

Lubricant contamination is the number one cause of lubricant-related equipment failure. The condition of your oil can make or break the operation of your turbines and other plant machinery. High-velocity oil flushing is essential to maintaining the health of your facility’s equipment.

Thanks to decades of experience executing high-velocity oil flushing services, our team can shorten traditional oil flushing timelines from months to weeks (or even days). B&W Energy Services has experience performing high-velocity oil flushing for companies including Shell, Chevron Phillips, Methanex, the Kuwait National Petroleum Company (KNPC), Samsung Engineering, CH2M Hill, Celanese, Zachry and more.

Table of Contents

- What is High-Velocity Oil Flushing?

- Why is Oil Flushing Important?

- The B&W High-Velocity Oil Flushing Difference

- How B&W Performs High-Velocity Oil Flushing

Get a Complimentary Oil Analysis

We also offer complimentary oil analyses to help you make more data-driven decisions. If you’re interested in a complimentary oil analysis, please contact our team, and a B&W representative will get back to you shortly.

Start Flushing Today

What is High-Velocity Oil Flushing?

High-velocity oil flushing cleans various contaminants from the oil and oil lines used within your facility’s equipment and turbines through a tried-and-true five-step method.

Why is Oil Flushing Important?

Lubricating oils are the lifeblood of your plant’s equipment. When particles and debris contaminate your lubrication systems, it can lead to expensive repairs and downtime later on.

Your lubrication systems may be contaminated during manufacturing, transport and installation at the project site. Atmospheric conditions like heat, dust, moisture and chemical vapors can also negatively affect lubrication systems.

Ensuring these systems are cleaned effectively through high-velocity hot oil flushing extends the life of your critical equipment and ensures long-term project success.

The B&W High-Velocity Oil Flushing Difference

- B&W’s specially designed equipment can perform a high-velocity oil flush in 5-7 days as opposed to the average 1-2 month process

- Smaller high-velocity oil flushing providers risk introducing contaminants to a project if they don’t properly evaluate each system or maintain clean equipment

- Our team ensures that your oil meets the appropriate particle count and fulfills OEM cleanliness specifications

- Learn what else sets us apart

How B&W Performs High-Velocity Oil Flushing

B&W Energy Services conducts high-velocity oil flushing lubrication services through the following five steps:

1. Evaluate

2. Plan

3. Model

4. Mobilize

5. Execute

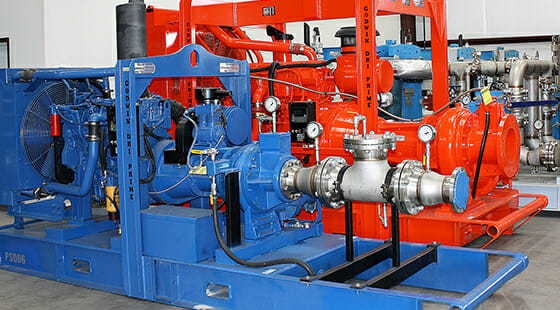

We design our high-velocity flushing skids in-house, complete with integrated pumping, filtration and heating components to create a minimum footprint. This allows for rapid mobilization and reduced rig-up time once on-site.

Our team also offers multiple skid options to tackle lube oil systems of different sizes, each equipped with variable frequency drives. Our equipment adapts to a wide range of flow rates to ensure that we complete a system clean in significantly less time than with onboard equipment. We can also provide hard-to-find specialty flushing kits, custom fittings and bearing jumpers.

At B&W, we understand the importance of preventing cross-contamination and potential leaks during the high-velocity hot oil flushing process. That’s why we meticulously inspect, clean and wrap each component before shipping it to the site.

Contact us to learn more about how your facility can benefit from B&W’s high-velocity oil flushing lubrication services.